Page 4 - Catalog 26 2019

P. 4

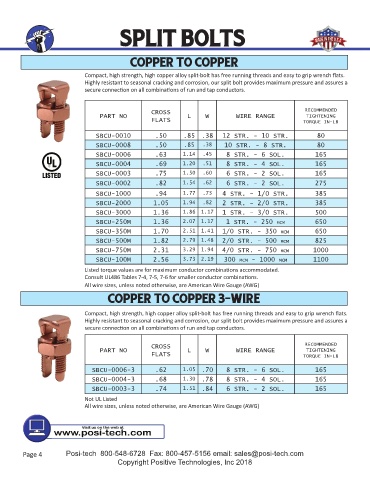

SPLIT BOLTS

COPPER TO COPPER

Compact, high strength, high copper alloy split-bolt has free running threads and easy to grip wrench fl ats.

Highly resistant to seasonal cracking and corrosion, our split bolt provides maximum pressure and assures a

secure connec on on all combina ons of run and tap conductors.

CROSS RECOMMENDED

PART NO L W WIRE RANGE TIGHTENING

FLATS TORQUE IN-LB

SBCU-0010 .50 .85 .38 12 STR. - 10 STR. 80

SBCU-0008 .50 .85 .38 10 STR. - 8 STR. 80

SBCU-0006 .63 1.14 .45 8 STR. - 6 SOL. 165

SBCU-0004 .69 1.20 .51 8 STR. - 4 SOL. 165

SBCU-0003 .75 1.50 .60 6 STR. - 2 SOL. 165

SBCU-0002 .82 1.54 .62 6 STR. - 2 SOL. 275

SBCU-1000 .94 1.77 .73 4 STR. - 1/0 STR. 385

SBCU-2000 1.05 1.94 .82 2 STR. - 2/0 STR. 385

SBCU-3000 1.36 1.86 1.17 1 STR. - 3/0 STR. 500

SBCU-250M 1.36 2.07 1.17 1 STR. - 250 MCM 650

SBCU-350M 1.70 2.51 1.41 1/0 STR. - 350 MCM 650

SBCU-500M 1.82 2.79 1.48 2/0 STR. - 500 MCM 825

SBCU-750M 2.31 3.29 1.94 4/0 STR. - 750 MCM 1000

SBCU-100M 2.56 3.73 2.19 300 MCM - 1000 MCM 1100

Listed torque values are for maximum conductor combina ons accommodated.

Consult UL486 Tables 7-4, 7-5, 7-6 for smaller conductor combina ons.

All wire sizes, unless noted otherwise, are American Wire Gauge (AWG)

COPPER TO COPPER 3-WIRE

Compact, high strength, high copper alloy split-bolt has free running threads and easy to grip wrench fl ats.

Highly resistant to seasonal cracking and corrosion, our split bolt provides maximum pressure and assures a

secure connec on on all combina ons of run and tap conductors.

CROSS RECOMMENDED

PART NO L W WIRE RANGE TIGHTENING

FLATS TORQUE IN-LB

SBCU-0006-3 .62 1.05 .70 8 STR. - 6 SOL. 165

SBCU-0004-3 .68 1.30 .78 8 STR. - 4 SOL. 165

SBCU-0003-3 .74 1.51 .84 6 STR. - 2 SOL. 165

Not UL Listed

All wire sizes, unless noted otherwise, are American Wire Gauge (AWG)

Page 4 Posi-tech 800-548-6728 Fax: 800-457-5156 email: sales@posi-tech.com

Copyright Positive Technologies, Inc 2018